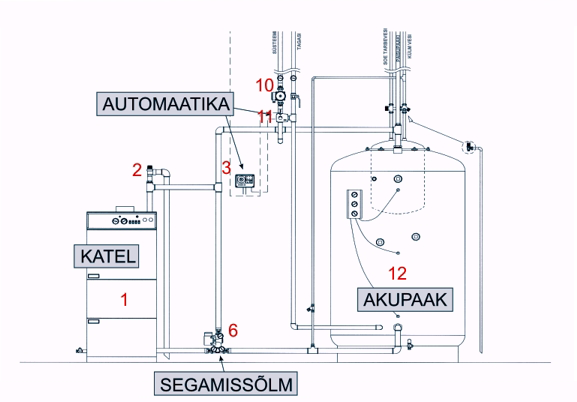

| 1 | Solid fuel boiler | 10 | Circulation pump |

| 2 | Safety valve | 11 | Mixing valve TERMOMIX (motor unit AUTOMIX-55) |

| 3 | Heating controller AUTOMIX 30Q | 12 | Accumulation tank |

| 6 | Loading units TERMOVAR or custom made |

The solid fuel boiler system presented below is whole, which ensures the proper functioning of all system components by using minimum number of required components and assemblies in the solution.

This small house boiler with all the necessary components is the best solution for the construction of a solid fuel boiler system.

System introduction.

The main components of the system are shown in the figures in the following pictures. It is possible to use solutions with one or more accumulation tanks depending on the size of the heated building and the possibilities of installing the accumulation tanks. The purpose of the system is to ensure the temperature of the water required for central heating as well as the hot water consumption, the minimum fuel and time required for day-to-day circulation.

Working principle

The proposed central heating system is divided into two separate parts for its purpose and purpose of operation, which are interconnected with a warm accumulation tank. The first part, or heating part, consists of a boiler, a boiler mixing unit and a connecting pipe. The purpose of the heating part is to ensure that the correct (sufficient) temperature, regardless of consumption, is constantly maintained in the accumulation tank . The second part, that is, the consumption part, consists of a heating system circulator, a heating pipe and heating elements (radiators, floor heating contours, etc.) and their regulators and valves. The purpose of the consumption section is to ensure the warmth of the premises (including domestic water) by using energy stored in the accumulation tank in a sustainable manner.

System

The system has three circuits circulating.

1. The first boiler circulator circuit consists of a boiler (1), a system safety valve (2), a mixing unit (6) between the boiler and the storage tank, and the tubes connecting them. The purpose of this circulator circuit is to reach the boiler's operating temperature as soon as possible in order to prevent excessive soiling and heat loss in the boiler as well to extend the lifespan of the boiler. The operation of this circle becomes clearer when getting to know more about the mixing unit between the boiler and the storage tank construction and operation.

2. The second, or accumulation circulation circle, is the next one in line. Adding storage tank, tanks (12) with associated equipment and piping to the system. The second ring starts to work when the boiler has reached its operating temperature (& gt; 65C) and the ring unit is opened, opening the path for the hot water into the accumulation tank. The accumulator tank has heat exchanger for the production of domestic water, which is a spiral tube, connected to the water pressure relief valve and the domestic water mixing unit. The domestic water mixing unit is a conventional three-way thermocouple that regulates the temperature of the hot water entering the DHW system.

3. The third, building circulation consists of a circulation pump (10), a mixer valve (the 3-way valve) (11), thermometers and automation equipment (3). They control the temperature and circulation of the central heating water passing through the central heating circuit of the building (floor heating elements, radiators, piping, etc.).

The proposed solution allows the rooms to be heated up quickly in a cooled system, as the hot water for the central heating circuit of the building is taken from the boiler from the pipe that is connected of the storage tank. Therefore, if the circulation pump (10) is running and the 3-way valve (11) is opened for circulation, the required amount of hot water is firstly taken directly from the boiler. The remaining hot water is then directed to the accumulation tank (12). When the boiler has burned off - the heating is completed, the water cycle from the accumulation tank continues for the central heating circuit of the building.

The temperature of the storage tank at the end of heating shuld be between +85 and + 95 ° C.

© 2002, instructions on the website of BAXI AB.